Delivering consistent quality and efficiency starts with precision. Our batter mixing systems, batter applicators, and SAPP (Sodium Acid Pyrophosphate) treatment solutions are engineered specifically for potato processors to ensure bright color, uniform coverage, and predictable performance across fries, wedges, hash browns, and specialty cuts.

Batter Mixing Systems: Maintain stable viscosity and recipe accuracy for consistent pick-up and reduced waste.

Batter Applicators: Achieve uniform coating with gentle handling and fast, hygienic changeovers.

SAPP Integration: Protect color and texture with controlled dosing and optimized contact time.

Combined with real-time monitoring and recipe-driven automation, our solutions help you minimize downtime, improve first-pass quality, and keep your potato lines running at peak performance.

BATTER SYSTEMS

BATTER MIXING SYSTEM

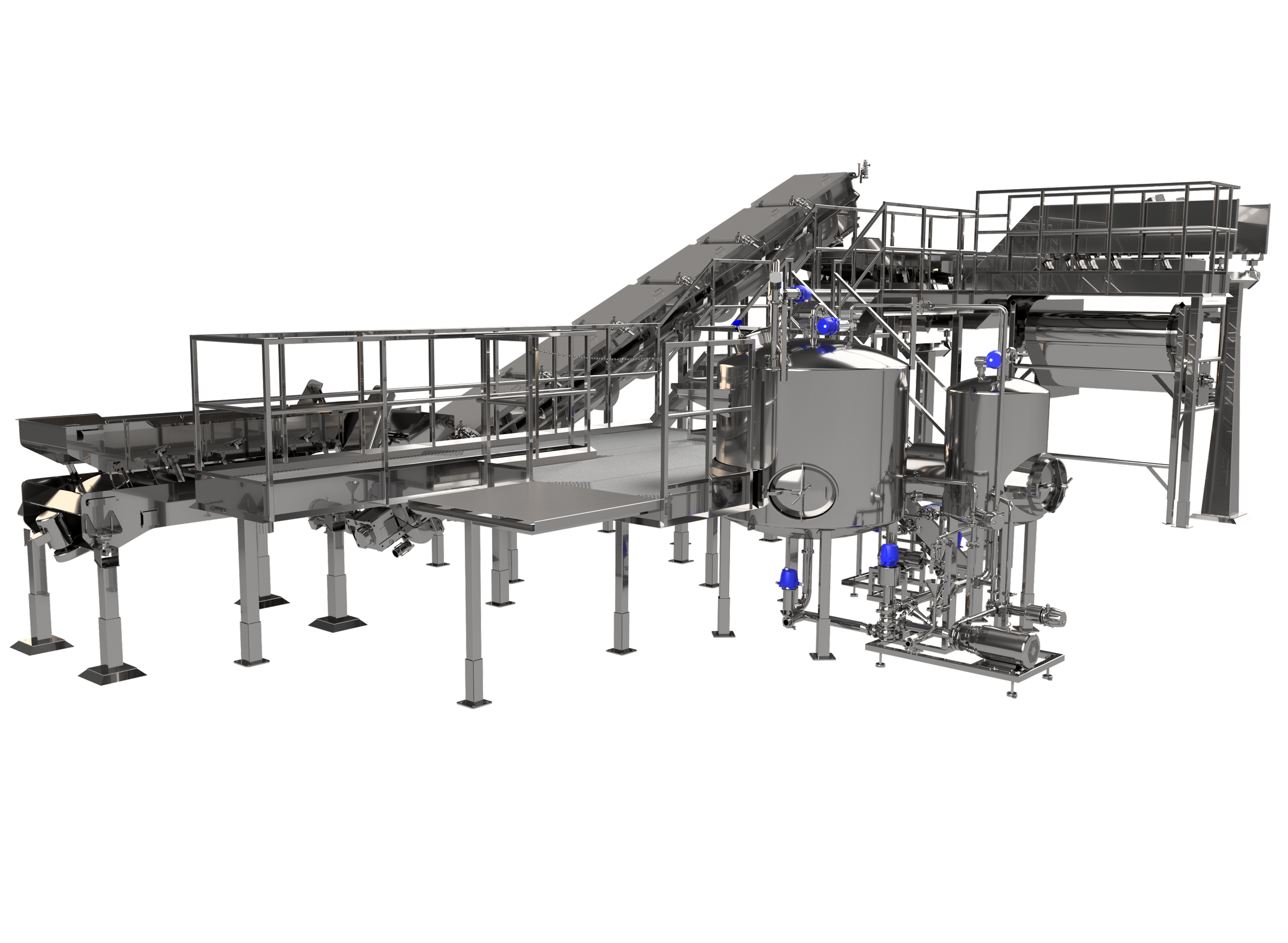

We manufacture a complete batter mix system and applicator conveyor for today’s modern French Fry plant. The system includes dry batter handling from the superbag to the dry batter hopper, filters, weigh feeders, batter mixing system, hydration tanks, Crylolators, and drum and weir style dosing conveyor system with batter capture and recirculation.

Batter Mixing System capable of handling, dispensing, mixing, and storing batter mixtures to the desired consistency and temperature.

Turnkey hygienic stainless-steel design

Wide range of batter rates, temperatures, and viscosities

Available with ingredients addition

BATTER APPLICATION SYSTEM

After drying, the potato strips are immersed in a prepared batter mixture run through conveyors or dipping system to ensure even coating and complete coverage before frying. With increased production and operating conditions, robust and wider batter applicator belts can withstand increasing load.

We design and manufacture:

Batter systems with up to 10-foot-wide belts

Heavy duty batter belts with redesigned side chain links to withstand pull and breakage

Clean-in-Place Hood construction for efficient sanitation and quicker turnover times between products

For products that require batter application before frying, GEM offers robust batter applicators that can handle various loads and operating conditions at high production rates. The products immersed in a prepared batter mixture run through conveyors or a dipping system to ensure consistent, uniform coating and complete coverage. Heavy-duty batter belts can be built up to 12 feet wide. With redesigned side chain links, the durable system withstands pull and breakage, which leads to reduced maintenance and extended service life. The batter applicator also has a Clean-in-Place hood construction for efficient cleaning and quicker turnover times between products

SAPP

Sodium acid pyrophosphate (SAPP) and dextrose are commonly applied to French fries or diced potatoes in a specialty line to control product color and maintain overall quality. This treatment occurs immediately after the blanching stage and before drying. Depending on plant capacity, line layout, and processor preference, the blanched product can be transferred to the SAPP/dextrose application system via flume, piping, or conveyor.